Understanding How Excavator Functions and Its Effect On Efficiency

Excavators play an important duty in building and mining operations, counting on a complex interaction of mechanical and hydraulic systems. Their capacity to carry out a selection of tasks rests on both their style and the technology incorporated within. Understanding these parts can substantially influence operational efficiency and performance. As advancements remain to improve the market, one have to consider how these adjustments will certainly influence future practices and performance.

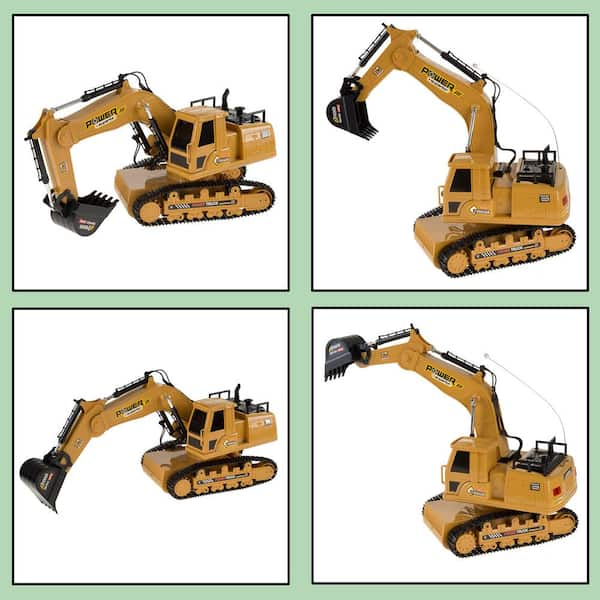

The Essentials of Excavator Mechanics

The Duty of Hydraulic Solutions in Excavators

At the heart of excavator procedure lies the hydraulic system, which plays a critical function in powering the equipment's motions and features. This system utilizes pressurized hydraulic fluid to move power, allowing numerous actions such as moving, training, and excavating. By using the principles of hydraulics, excavators can carry out tasks with amazing precision and force, enhancing overall functional efficiency.The hydraulic system contains vital parts, consisting of pumps, shutoffs, and cyndrical tubes, which collaborate to regulate the circulation and instructions of the liquid. When the operator engages the controls, the hydraulic liquid is routed to certain cyndrical tubes, equating the operator's commands right into physical motion. This system permits smooth and receptive actions, which are crucial in building and construction and excavation atmospheres. double e volvo rc excavator. The effectiveness of the hydraulic system straight affects the efficiency and versatility of the excavator, making it an indispensable element in modern-day excavation processes

Trick Elements of an Excavator

Comprehending the essential parts of an excavator is vital for grasping exactly how this powerful equipment operates. An excavator contains a number of significant elements, consisting of the undercarriage, home, arm, boom, and pail. The undercarriage offers stability and flexibility, usually including tracks or wheels to browse different terrains. Your house consists of the engine and hydraulic systems, enabling the driver to regulate movement and power the machine. The boom prolongs from the house, making it possible for vertical reach, while the arm attaches to the bucket, promoting digging and training operations.Additionally, the cab houses the driver, furnished with controls for specific maneuvering. Each of these elements plays an important function in the excavator's total performance, adding to its efficiency and effectiveness on construction sites. Understanding these components helps in preserving and optimizing excavator performance, making certain tasks are finished securely and efficiently.

Add-on Versatility and Its Advantages

Add-on flexibility is a vital facet of excavators, making it possible for operators to switch between different devices customized for details jobs. This adaptability not only enhances task effectiveness however also adds to cost-effectiveness by lowering the demand for multiple machines. Understanding the different kinds of attachments available can considerably influence the total efficiency and capability of an excavator on job sites.

Kinds of Accessories

While excavators are mostly identified for their excavating capacities, their real convenience hinges on the wide selection of add-ons readily available. These accessories improve the excavator's functionality, allowing it to execute numerous jobs beyond excavation. Common attachments consist of pails (for excavating and scooping), hydraulic thumbs (for realizing products), and augers (for drilling holes) Grapples are used for moving and handling particles, while rippers can damage up hard surface areas. Various other specialized attachments, such as plates and rakes, allow excavators to adapt to particular job needs. This diversity not just raises the maker's utility across different sectors, including landscape design, building, and demolition, but also enables drivers to tailor their devices to fulfill particular task demands successfully.

Boosted Job Performance

Making best use of work effectiveness is a primary benefit of utilizing different excavator attachments. Different add-ons allow an excavator to perform several jobs without requiring to change devices, conserving useful time and labor. Making use of a hydraulic hammer can break concrete while a container accessory can dig deep into dirt, enabling a seamless process. This versatility minimizes downtime associated with devices adjustments and enhances efficiency on-site. In addition, specialized add-ons improve precision in jobs such as grading or landscape design, resulting in greater top quality outcomes. The capability to adapt to different task needs not just streamlines operations but also reduces the requirement for extra machinery, making sure that tasks are finished promptly and properly. On the whole, add-on convenience substantially adds to raised work performance in excavation job.

Cost-Effectiveness and Adaptability

Cost-effectiveness is a considerable advantage of utilizing versatile excavator add-ons. These add-ons permit a solitary excavator to carry out multiple tasks, lowering the demand for extra machinery and labor - double e volvo rc excavator. By switching in between buckets, hammers, and grapples, drivers can deal with various projects, from excavating to demolition, therefore optimizing devices usage. This adaptability not only lowers functional prices yet likewise lessens downtime connected with changing equipment. over at this website Furthermore, the capability to customize excavators with specialized attachments boosts performance, as they can effectively deal with diverse jobs according to task demands. In conclusion, the mix of cost-effectiveness and flexibility in excavator attachments adds to boosted operational effectiveness and source allotment in building and excavation projects

Advanced Technology in Modern Excavators

Modern excavators are progressively outfitted with innovative technology that transforms excavation processes. Automation improves operations, while enhanced gas effectiveness decreases operational prices. In addition, wise control systems enhance accuracy and safety, marking a significant development in excavation equipment.

Automation in Excavation Processes

As excavation technology advances, automation has actually become an essential part in enhancing effectiveness and precision on job sites. Modern excavators are outfitted with innovative automated systems that promote jobs such as grading, digging, and trenching with marginal operator intervention. These systems utilize sensing units, GPS, and device understanding algorithms to assure precise placing and depth control, substantially decreasing the margin for mistake. Additionally, automation enables drivers to concentrate on critical decision-making as opposed to hands-on controls, leading to enhanced performance in general. Such technologies not only enhance operations but likewise boost safety by lessening human mistake in complex operations. The combination of automation in excavation procedures stands for a considerable development in building innovation, driving the sector in the direction of better efficiency and effectiveness.

Enhanced Fuel Performance

Advancements in technology have also resulted in considerable enhancements in fuel effectiveness for contemporary excavators. Modern makers are furnished with innovative link engines that enhance power result while decreasing fuel consumption. These engines utilize innovative combustion innovations, such as turbocharging and direct gas shot, to improve performance and effectiveness. Additionally, lightweight products in building and construction lower general weight, permitting less energy expense throughout procedure. The introduction of variable speed controls enables drivers to change engine performance according to specific jobs, better decreasing gas use. Consequently, these improvements not just lower functional prices however also add to environmental sustainability by reducing exhausts. On the whole, enhanced gas effectiveness in excavators is a vital development that reinforces productivity and financial practicality in the building sector.

Smart Control Equipment

While operators browse progressively intricate task websites, wise control systems in excavators have become important devices for enhancing efficiency and accuracy. These advanced innovations use sensors and formulas to keep an eye on various specifications such as load weight, surface conditions, and operational performance. By immediately adjusting hydraulic functions, clever systems enhance machine efficiency, leading to enhanced efficiency and lowered wear on elements. In addition, operators gain from user-friendly interfaces that supply real-time feedback and diagnostics, enabling educated decision-making. This integration of innovation not just simplifies operations however additionally decreases human error, adding to safer work atmospheres. As the building and construction industry continues to progress, clever control systems will play an important duty fit the future of excavator efficiency and efficiency.

Enhancing Operational Effectiveness With Excavators

Excavators play a crucial role in enhancing operational efficiency across various building and excavation jobs. Their adaptability permits numerous tasks, including digging, material, and lifting handling, which streamlines process and reduces the need for added equipment. With effective hydraulic systems, excavators can do durable jobs with accuracy, considerably decreasing the time required to total tasks. The integration of advanced technology, such as general practitioner and automated controls, better enhances their procedure, enabling operators to accomplish greater accuracy and decrease product waste. Additionally, modern excavators are developed to consume less fuel and lessen emissions, adding to both cost financial savings and ecological sustainability. By using excavators efficiently, construction groups can enhance efficiency, satisfy job deadlines, and enhance total site monitoring. This multifunctionality and performance make excavators crucial devices in the contemporary building and construction landscape.

The Future of Excavators in Construction and Mining Industries

As the construction and mining sectors evolve, the future of excavators is poised for substantial transformation driven by technical development and altering operational needs. Breakthroughs in automation and expert system are reshaping excavator abilities, permitting boosted precision and efficiency in procedures. Self-governing excavators are arising, minimizing the requirement for human treatment and reducing the danger of accidents.Moreover, the assimilation of telematics and IoT modern technology allows real-time surveillance of device performance and predictive maintenance, optimizing uptime. Environmentally friendly styles, including electric and hybrid designs, are acquiring traction, lining up with sustainability goals within the industry.Additionally, the usage of innovative materials and lighter designs improves fuel performance while maintaining performance criteria. As these fads progress, excavators will certainly play an important duty in satisfying the enhancing needs for efficiency and security in building and mining, eventually transforming operational landscapes.

Often Asked Inquiries

Exactly How Do Weather Condition Conditions Impact Excavator Efficiency?

Weather significantly influence excavator efficiency, as rain and mud can hinder traction and stability, while extreme temperatures may impact hydraulic systems. Operators has to adapt to these variables to ensure suitable performance and safety throughout operations.

What Safety And Security Procedures Should Operators Comply With While Using Excavators?

Safety and security look at these guys actions for excavator drivers consist of wearing suitable individual safety equipment, carrying out pre-operation assessments, guaranteeing appropriate communication with ground personnel, keeping a risk-free range from overhead risks, and adhering to recognized functional procedures to stop crashes.

Exactly How Typically Should Excavators Be Preserved for Ideal Performance?

Excavators must be maintained frequently to guarantee peak efficiency, generally every 250 operating hours or as defined by the supplier. Regular checks boost integrity, avoid unexpected break downs, and prolong the lifespan of the equipment.

What Is the Typical Life Expectancy of an Excavator?

The typical lifespan of an excavator commonly varies from 10,000 to 15,000 hours of procedure. Factors affecting longevity include maintenance techniques, operating problems, and the high quality of the maker itself, impacting overall performance and efficiency.

Can Excavators Operate Unequal Terrain Properly?

Excavators can run successfully on irregular surface as a result of their expressed styles and adjustable tracks. These attributes permit them to maintain security and traction, enabling efficient operation in challenging environments typically come across in building and construction and landscaping tasks. Each of these elements plays a crucial role in the excavator's overall performance, adding to its effectiveness and performance on construction websites. Optimizing work performance is a main advantage of utilizing different excavator accessories. While drivers browse significantly complicated job websites, wise control systems in excavators have emerged as crucial tools for boosting effectiveness and precision. Excavators play a crucial role in enhancing functional performance throughout different building and construction and excavation tasks. Advances in automation and fabricated knowledge are improving excavator capacities, permitting for improved accuracy and performance in operations.